3D inspection and material loss analysis software

What is Fovea

Extract corrosion and other defects from any shape, without any reference.

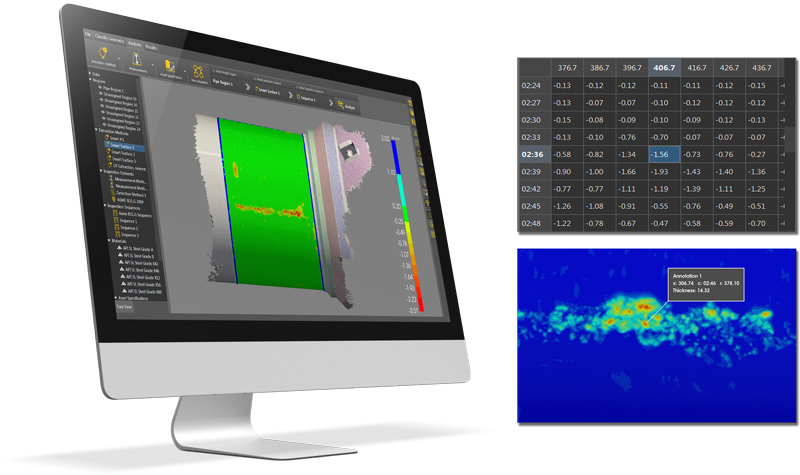

Fovea is a professionnal inspection software that lets you process the data from 3D scanners to extract material loss and corrosion measurements with high accuracy.

Fovea's algorithms filter mechanical damage and other geometric deformations to generate an accurate reading of the material loss. It is the perfect solution for the analysis of localized defects, or for many real-life scenarios where it is inadequate to compare the part with a reference model.

Complex Shape Inspection

From any tubular shape to geometries such as cylinders, cone, elbows, spheres and beams, it is possible to accurately extract measurements.

Code Compliant

Flexible calculation templates ensure compatibility with most international and national standards and codes.

Smart AI Algorithms

Automated measurements with AI algorithms ensure the safety of your inspection process with conservative and repeatable measurement methods.

Why Fovea

Because your time matters.

Solutions built around Fovea improve inspection efficiency by increasing safety, accuracy and data quality, while providing better turnarounds.

Quick Turnaround

Reduce by 10X or more the time spent measuring on-site, compared to pit gauge and UT measurements.

Compatible with all Professionnal 3D Scanners

Pick any 3D scanner from a wide range of manufacturers.

High Traceability

Ensure 100% coverage of damaged areas and keep track of all measurements and calculations.

Easy to Learn

Inspection templates and automation simplify the workflow and the writing of procedures.

Applications

Versatile and universal, Fovea is used to solve material loss assessments on pipelines, pressure vessels, storage tanks, boiler tubes, piping components, ship hulls and structural beams.

Storage tank inspection

Fovea, combined with a fast 3D scanner, is a superior solution to measure corrosion on shell plates, bottom plates and their welding joints.

Pipeline inspection

With its unparalleled smart surface solver, Fovea is used to measure corrosion on bends, pipe wrinkles and general corrosion assessments that are very challenging with other methods.

testimonials

First choice solution for corrosion assessments

As a market leader in 3D scanning for integrity assessments, Fovea has made a huge difference to our business. Being able to generate accurate, repeatable results in such a short time has allowed us to get the most out of our 3D data across a whole range of industry applications. This is our first choice solution for any type of corrosion assessment.